Reciprocating Compressor Products

FICS has years of experience developing and building the following compressor products. Each is available with a documentation package created for your specific equipment. These include bill of materials, arrangements, label listings, and operator manuals with unique tagging specific to your equipment. We can comply to your site specifications and acceptable manufacturer lists. Equipment can be configured to meet API 618 requirements. Products utilize hazardous area equipment and methods to operate in the compressor area.

Cylinder Lubricators

Cylinder lubricators are lubrication systems designed to lubricate the cylinder bore and packings of the compressor. Lubricators are available as the series progressive or pump to point type. Equipment design and function will be tailored to your requirements.

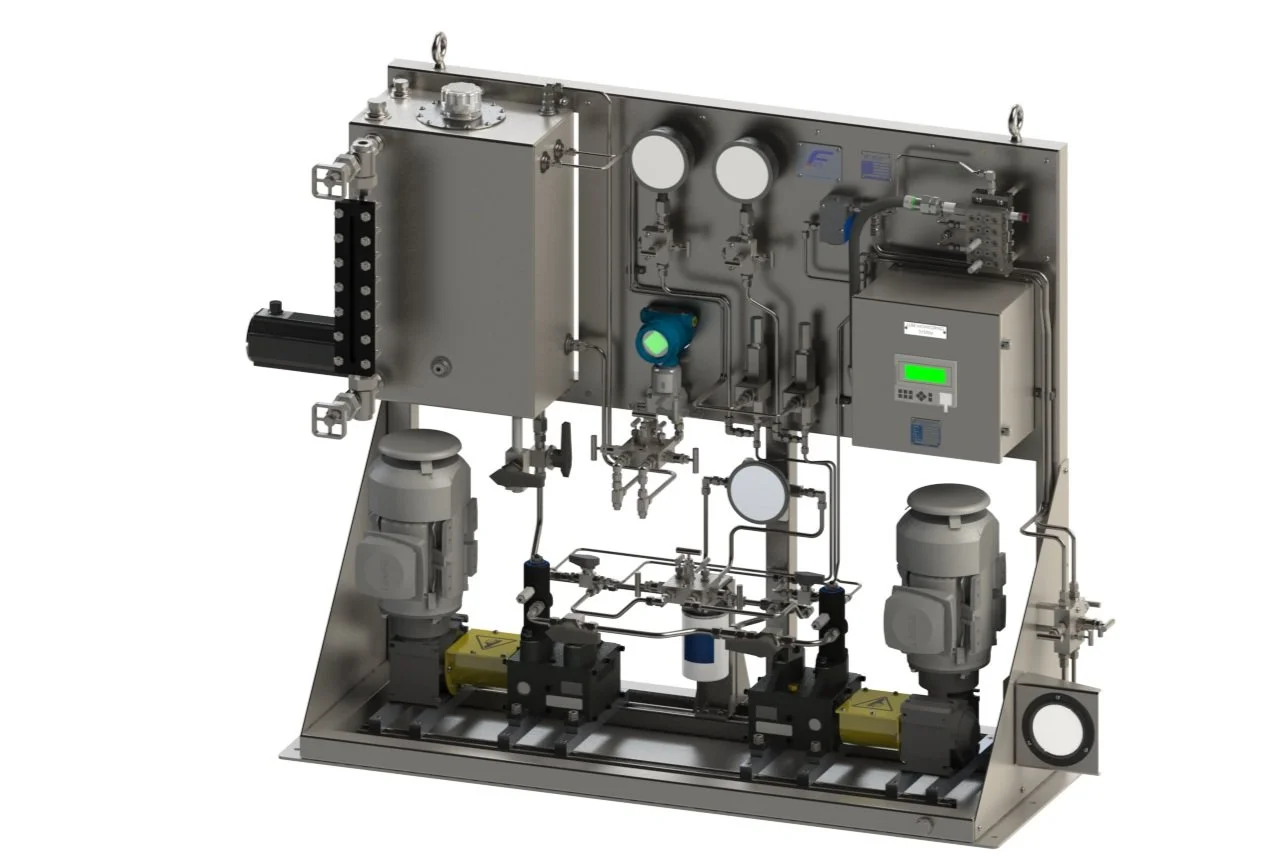

Buffer Panels

Buffer panels are designed for multiple purposes including collecting process gas leakage, monitoring packing condition, preventing an explosive atmosphere from developing, and atmospheric fugitive emission control. Buffer panels are available as the constant pressure or variable pressure type. Equipment design and function will be tailored to your requirements.

Control Systems

Control panels are designed to operate the compressor and monitor instrument signals. Systems can be as simple as several manual operators or a full control panel consisting of a PLC, I/O, and HMI UL Listed Control Panels can be provided. Equipment design and function will be tailored to your requirements.

Capacity Control Systems

Capacity control systems are designed to control the operation capacity of the compressor discharge pressure. Capacity control systems are available as step control or infinite step controllers (ISCs). Step control utilizes cylinder unloaders to control discharge pressure at specific capacity increments. ISCs control discharge pressure at any capacity percentage. Equipment design and function are standardized to fit all applications. Step capacity can be configured for the number of steps required.